ZippiAi : Your Intelligent AI Engine for Equipment Troubleshooting

- Upinder Singh

- Jun 20

- 3 min read

Updated: Jun 25

In modern manufacturing, predictive maintenance is a valuable tool. It helps reduce risk and anticipates some equipment failures before they happen. But let’s face it machines still fail unexpectedly, even with the best predictive models in place. When that happens, the clock starts ticking, downtime adds up, and productivity takes a hit.

This is where ZippiAI steps in not as another dashboard or analytics tool, but as a real-time, intelligent AI troubleshooting engine that empowers your workforce with immediate, context-aware solutions. ZippiAi not only diagnoses the problems but also helps your team solve them faster, smarter, and more efficiently than ever before.

Why Traditional Troubleshooting Still Holds Us Back

The harsh reality of industrial operations is that, when equipment breaks down, the process of troubleshooting is still painfully outdated. Technicians often rely on old manuals, scattered notes, and delayed responses from OEMs or experts. Even experienced teams are forced into a trial-and-error cycle, wasting valuable time and exposing your operation to costly delays.

What’s missing isn’t human effort it’s real-time, actionable knowledge. And that’s exactly what ZippiAI delivers.

For Instant, Intelligent Diagnosis that Moves at Machine Speed, ZippiAI integrates directly with your equipment’s sensors, telemetry, and historical performance data. As soon as a fault occurs, it gets to work analyzing real-time inputs, comparing them with known patterns, and identifying the root cause with exceptional accuracy.

This AI-powered diagnostic process takes seconds, not hours. Your team no longer has to guess, dig, or wait. They get a clear explanation of what’s wrong and more importantly, how to fix it right when they need it most.

Guided Troubleshooting Powered by AI Agents

Identifying the issue is only half the battle. ZippiAi goes further by acting as a knowledgeable AI agent that walks technicians through a personalized repair process, step by step.

Instead of flipping through technical manuals or calling for backup, technicians can ask ZippiAI directly. The system responds with clear, contextual guidance based on the specific machine model, error code, and scenario. It provides wiring diagrams, torque specifications, safety notes, part numbers, and more right at the point of need. With visual aids and logical instructions, even less experienced staff can resolve complex issues confidently.

Access to a Living, Evolving Knowledge Base

ZippiAI is not limited to pre-programmed responses or static instructions. It taps into a vast digital ecosystem including OEM documentation, company-specific SOPs, service records, and even curated industry forums. It constantly pulls and synthesizes relevant information to answer complex questions and adapt to new problems as they emerge.

This gives your team immediate access to the best possible information not just what’s written in a manual, but what’s been learned and shared across the entire organization (and beyond).

Continuous Learning That Improves Every Interaction

Every time ZippiAI helps solve a problem, it learns. Each interaction feeds into its AI engine, enriching its diagnostic capabilities and refining future responses. Over time, your troubleshooting knowledge base becomes deeper, smarter, and more personalized to your environment and equipments. This learning process also enhances your predictive maintenance systems. Real-time resolution data is looped back into your analytics pipeline, making your entire operation more proactive and reliable.

In a time when experienced technicians are retiring and newer staff are still learning the ropes, ZippiAI plays a critical role. It acts as an always-available digital expert, helping less experienced technicians tackle difficult issues without relying on a shrinking pool of specialists. Rather than replacing humans, ZippiAI augments your team filling in knowledge gaps, supporting standardization, and increasing technician confidence and capability. The result is faster repairs, fewer errors, and stronger operational resilience.

Building a More Reliable, Scalable Maintenance Operation

By dramatically reducing downtime, improving resolution time, and empowering every technician, ZippiAI doesn’t just solve one-off problems ,it strengthens your entire maintenance and supply chain infrastructure.

Whether you're operating in packaging, food processing, automotive, or heavy industry, ZippiAI integrates smoothly across multiple equipment types and vendors. It helps your teams move from reactive firefighting to systematic, AI-enhanced problem-solving at scale.

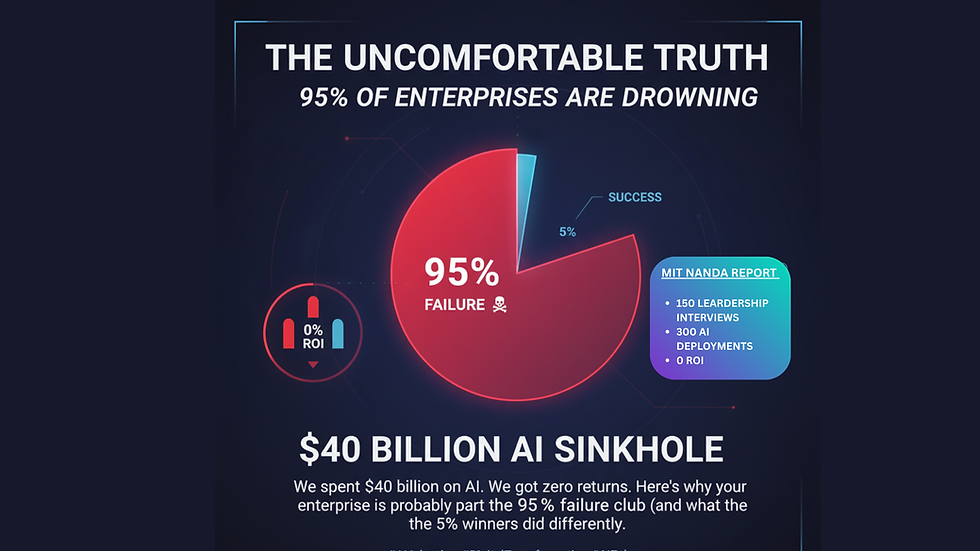

Unlike many AI tools stuck in endless pilot testing, ZippiAI delivers immediate ROI and is designed to scale across facilities, regions, and teams. No long setup. No integration nightmares. Just proven, industrial-strength AI support where and when it matters most.

A New Era for Equipment Troubleshooting

ZippiAi represents a bold shift in how manufacturers handle troubleshooting. It's not just about faster diagnostics it's about building an adaptive, intelligent infrastructure that supports technicians, accelerates resolutions, and strengthens operations. With ZippiAI, your machines talk, your data works harder, and your team gets the support they need to keep production flowing without delays, confusion,or downtime.

Comments